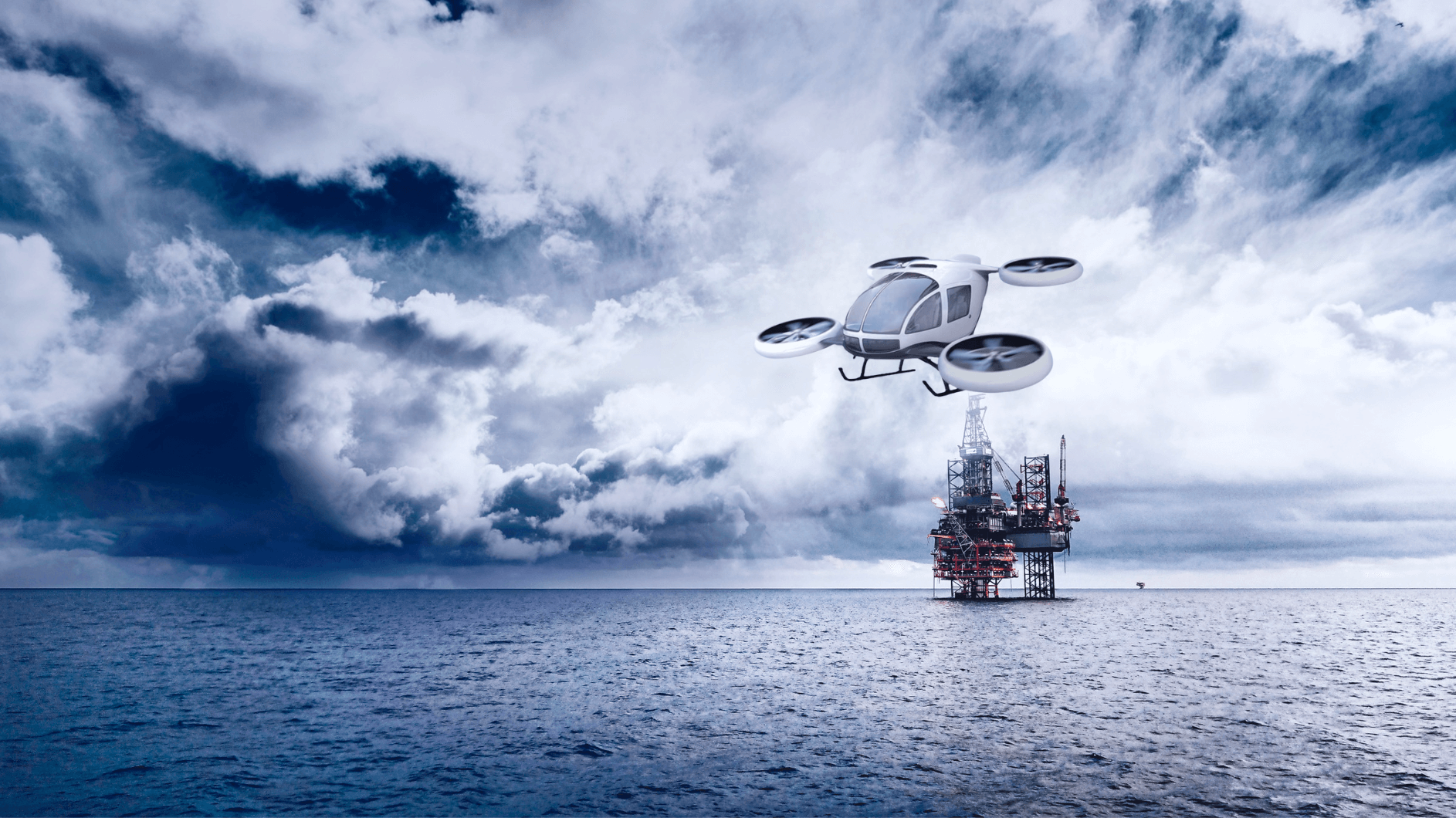

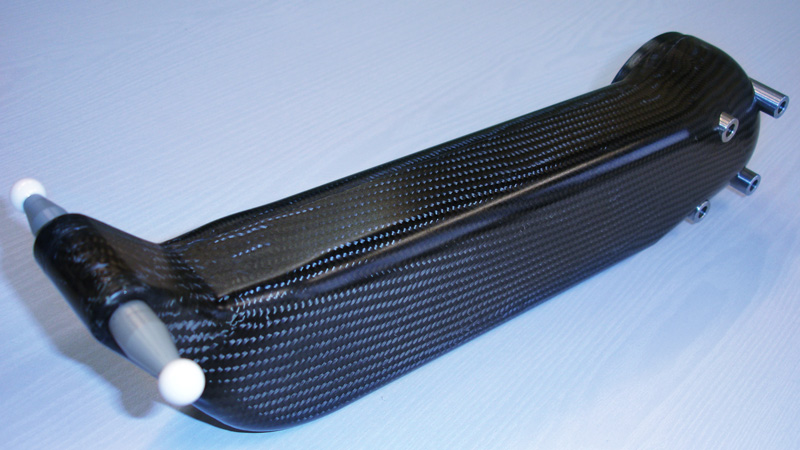

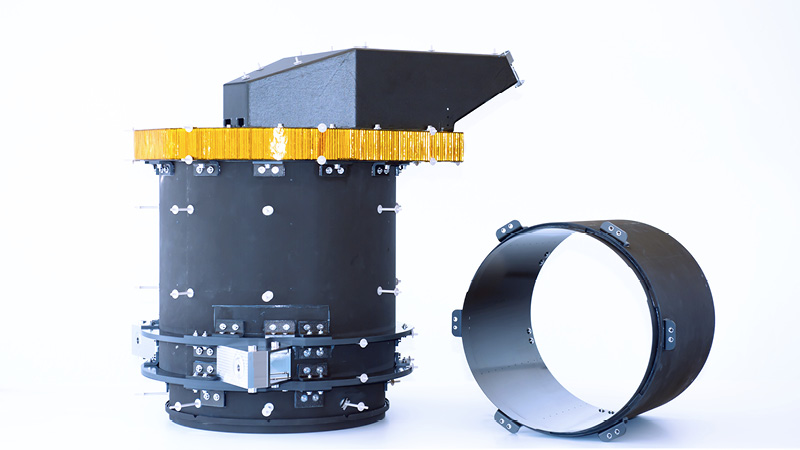

Aviation

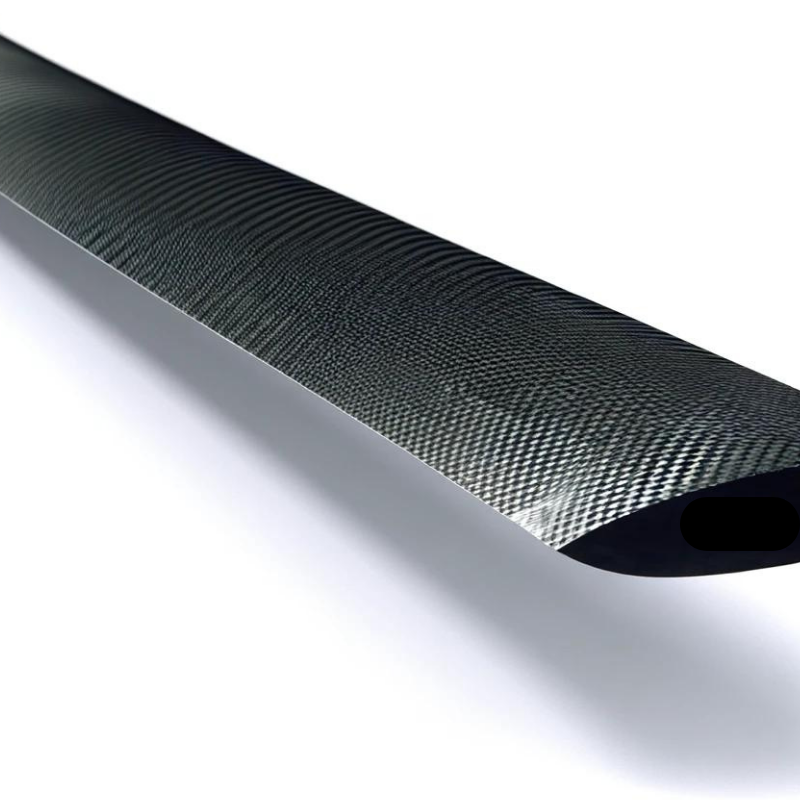

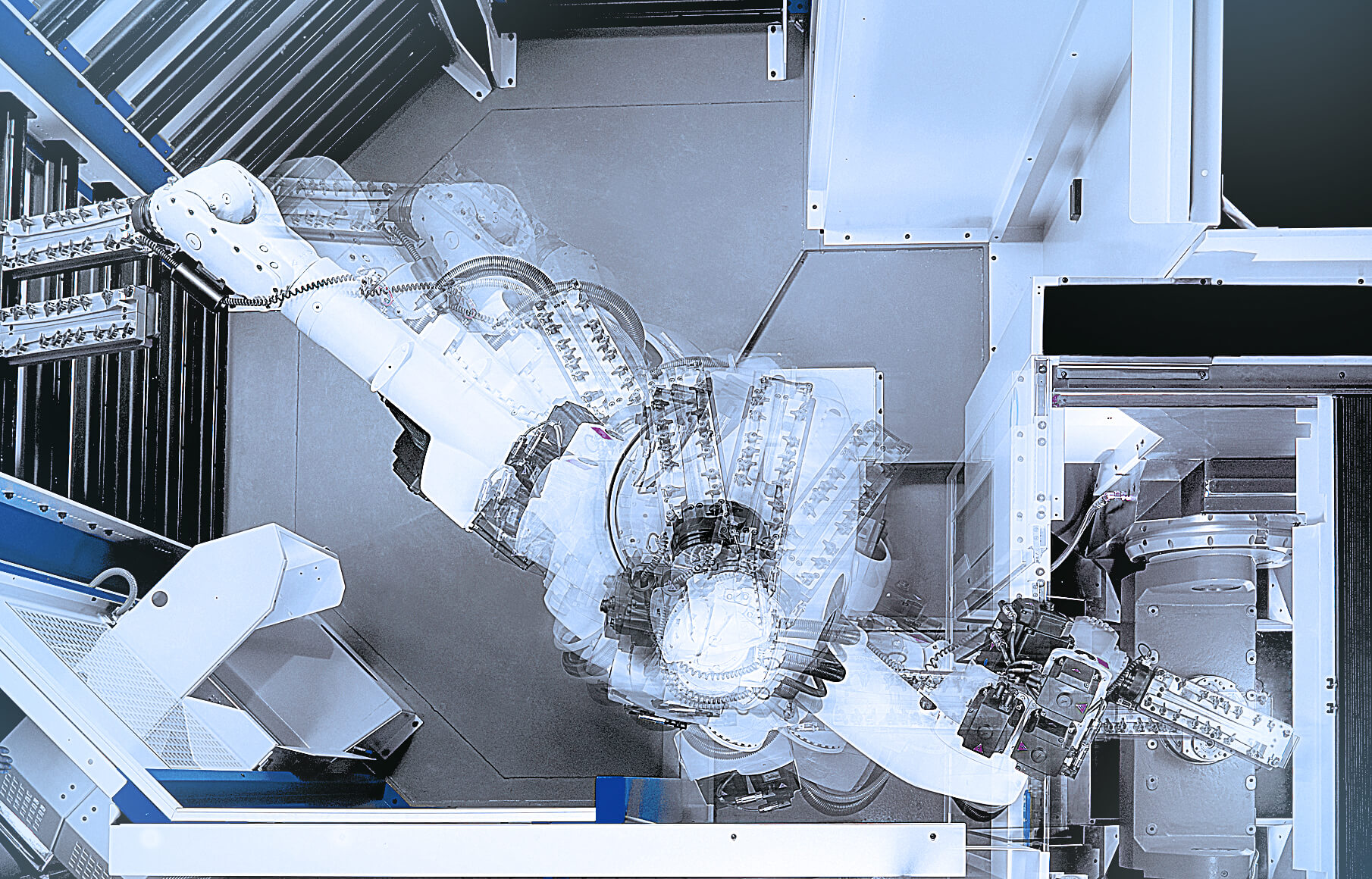

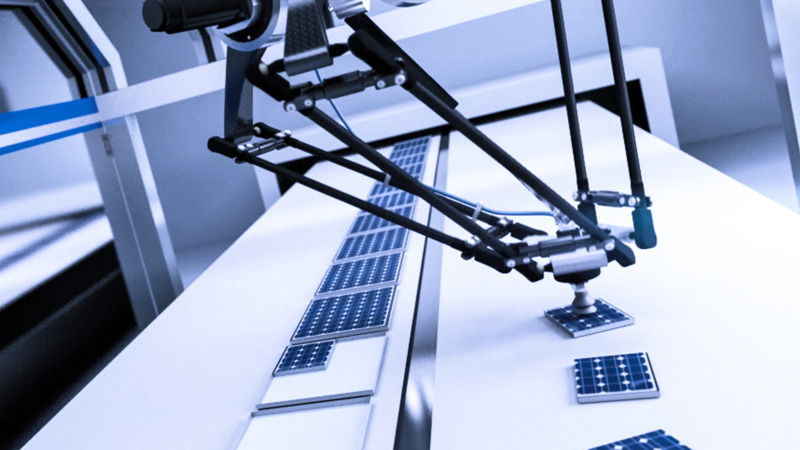

Connova Group is involved in the aviation industry for more than 20 years. With our ultra-light and ultra-stiff composite components, we increase the efficiency and lower the operating cost of experimental planes, commercial aircrafts, business jets, military jets, helicopter, and drones. We provide a broad experience in this specific segment and convince with our individual solutions.