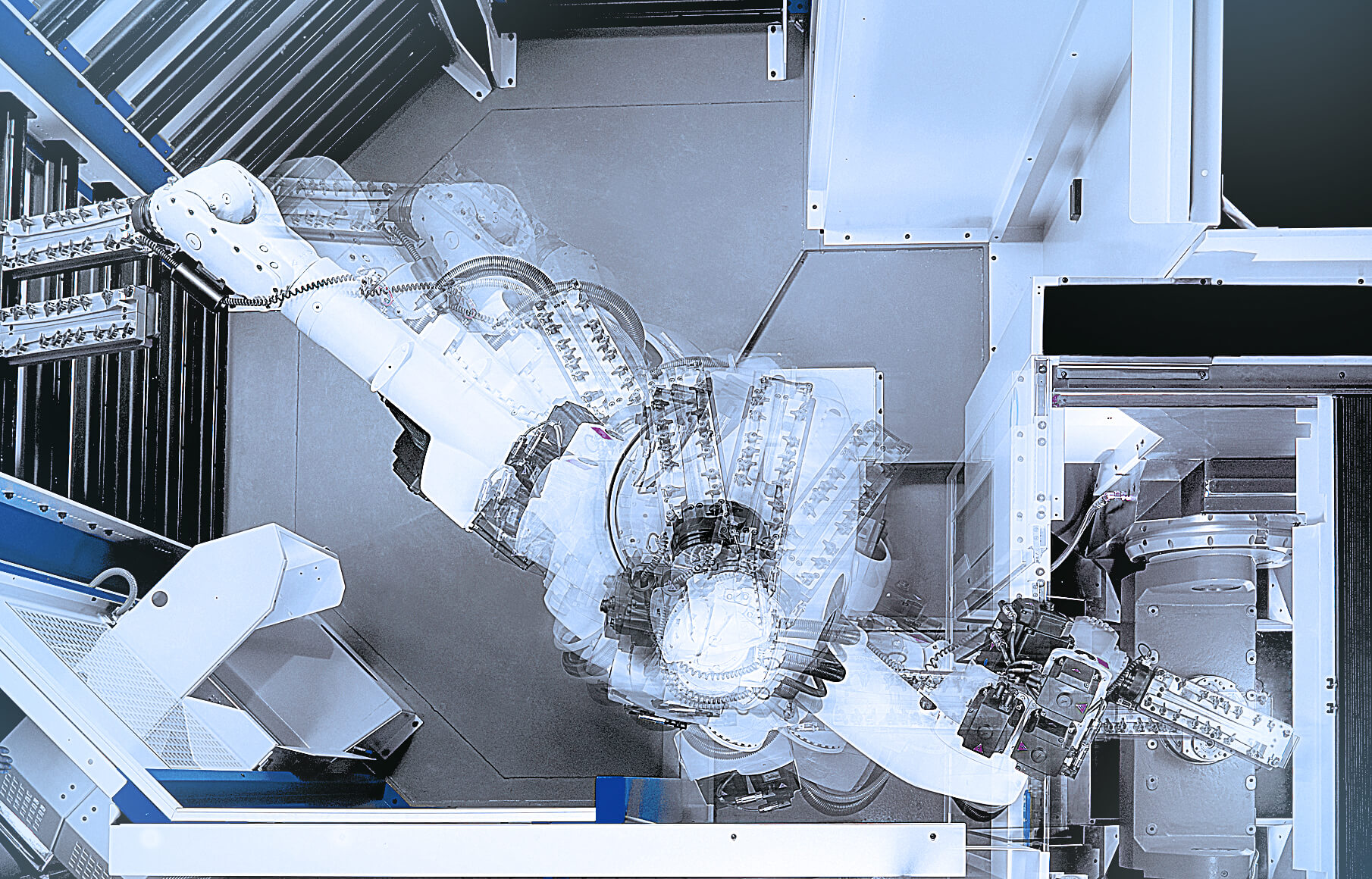

Composite Components

New Ways in Composites: being prototype or serial production, being Carbon, Glass, Aramid, or natural fibres, Connova Group manufactures composite components in perfection.

We realize your ideas and plans until full product maturity. Our experience, our drive for innovation and our versatility guarantees high-quality products without compromise.

We bring the extra-ordinary material properties of composites literally to carry loads.