To understand the material, to keep up with time.

Process development and work preparation

High-accurate manual work must be prepared well

As soon as the definition of the composite part is completed, it is normally transferred to production.

Our process engineers translate the specifications of the designers to manufacturing-relevant documents and instructions for the production team. Thus, we always have to full process from A to Z in mind, which consists typically by these steps:

- To cut and sort the plies by means of a cutting table (“cutter”) – prepregs or dry fabrics

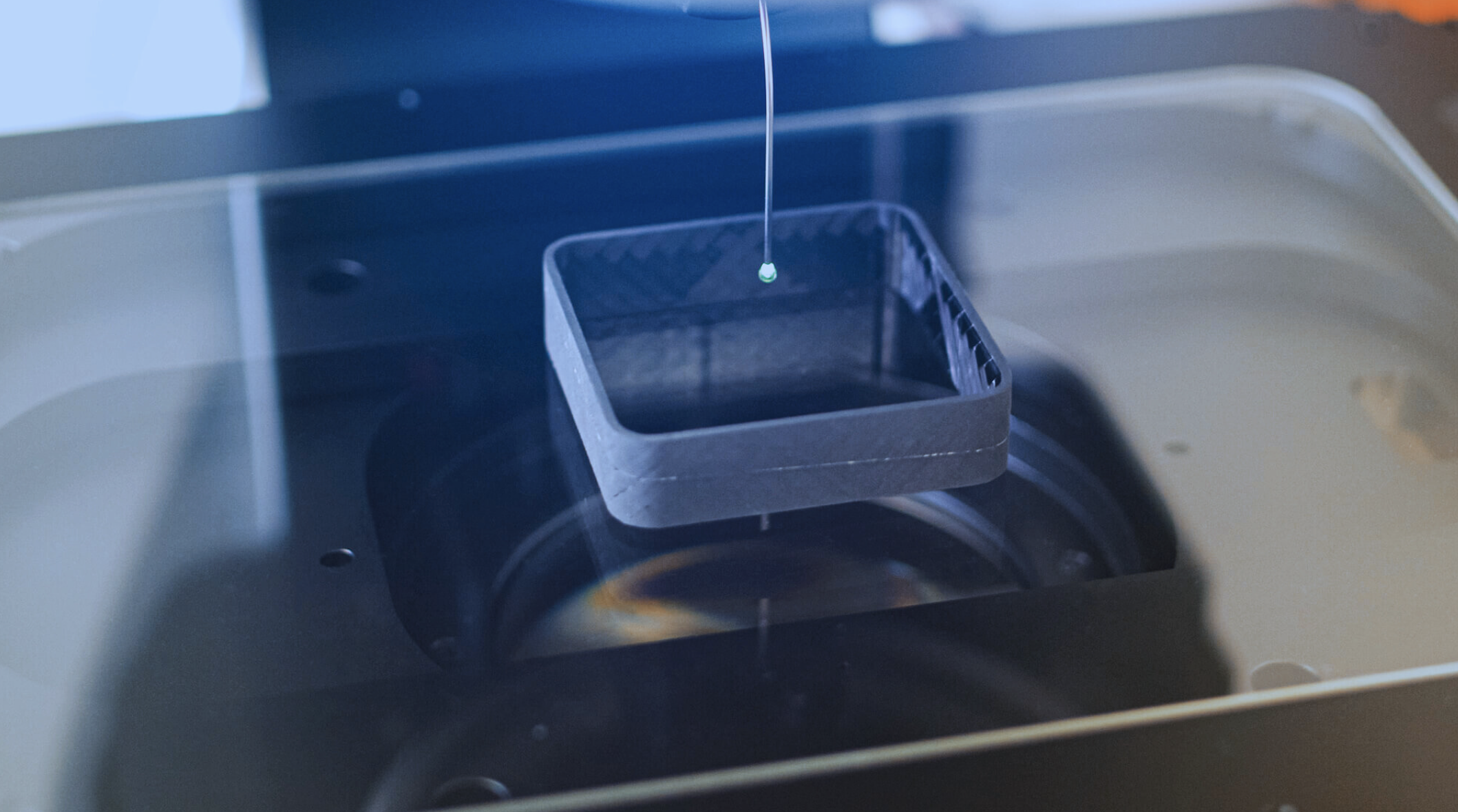

- To laminate or preform the plies into moulds

- To prepare the vacuum bag and to check the tightness

- To cure the part(s) while applying pressure and temperature, e.g., autoclave, press, oven, etc.

- To demould the parts and to clean roughly from resin residuals

- To mechanically machine the parts (CNC milling, trimming, drilling, sawing, deburring, etc.)

- To apply structural adhesive bonding, to assemble, to install, to mount, etc.

- To apply surface treatment, e.g., grinding, painting, polishing, sealing, etc.

- To measure, to inspect, to check, etc.

- To pack and ship the deliveries

All these process steps are elaborated and documented in detail before starting the production. If needed, parameters are defined and set based on pre-series production samples.

Alle diese Prozessschritte werden im Vorfeld der Produktion detailliert ausgearbeitet und beschrieben. Falls erforderlich werden die genauen Parameter in Fertigungsversuchen ermittelt und dokumentiert.

Our services include:

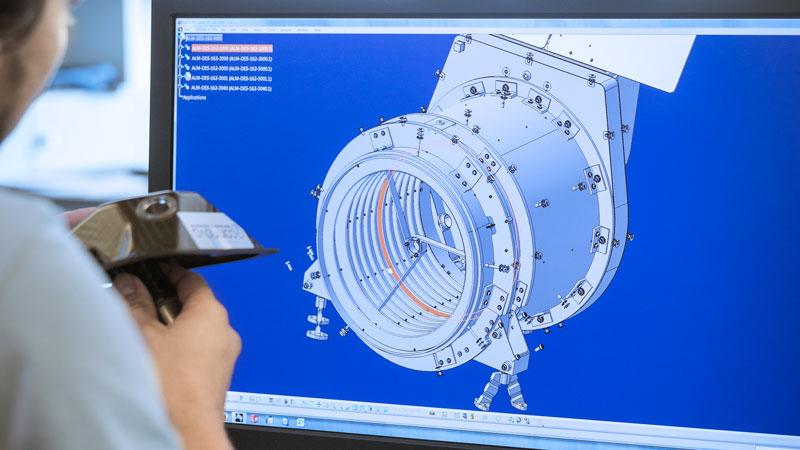

- Creation of manufacturing documents and drawings

- Creation of manufacturing instructions

- Especially for the composite manufacturing shop, creation of the so-called ply book

- Creation of laser projection data

- Creation of CAM programs and set-up instructions