CNC machining in best shape

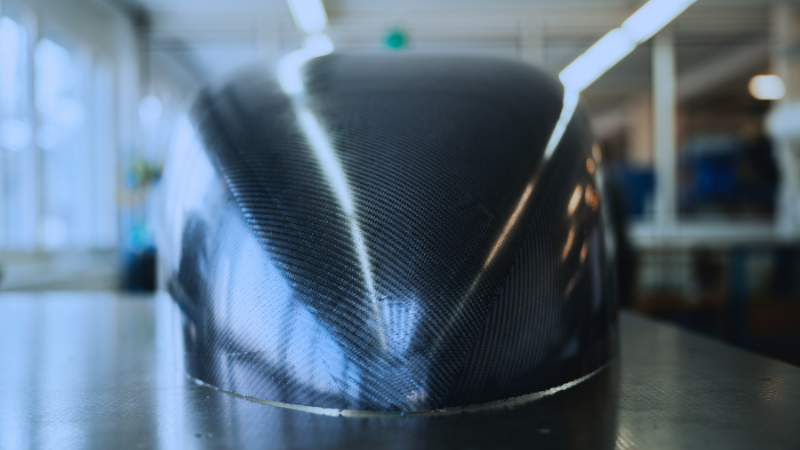

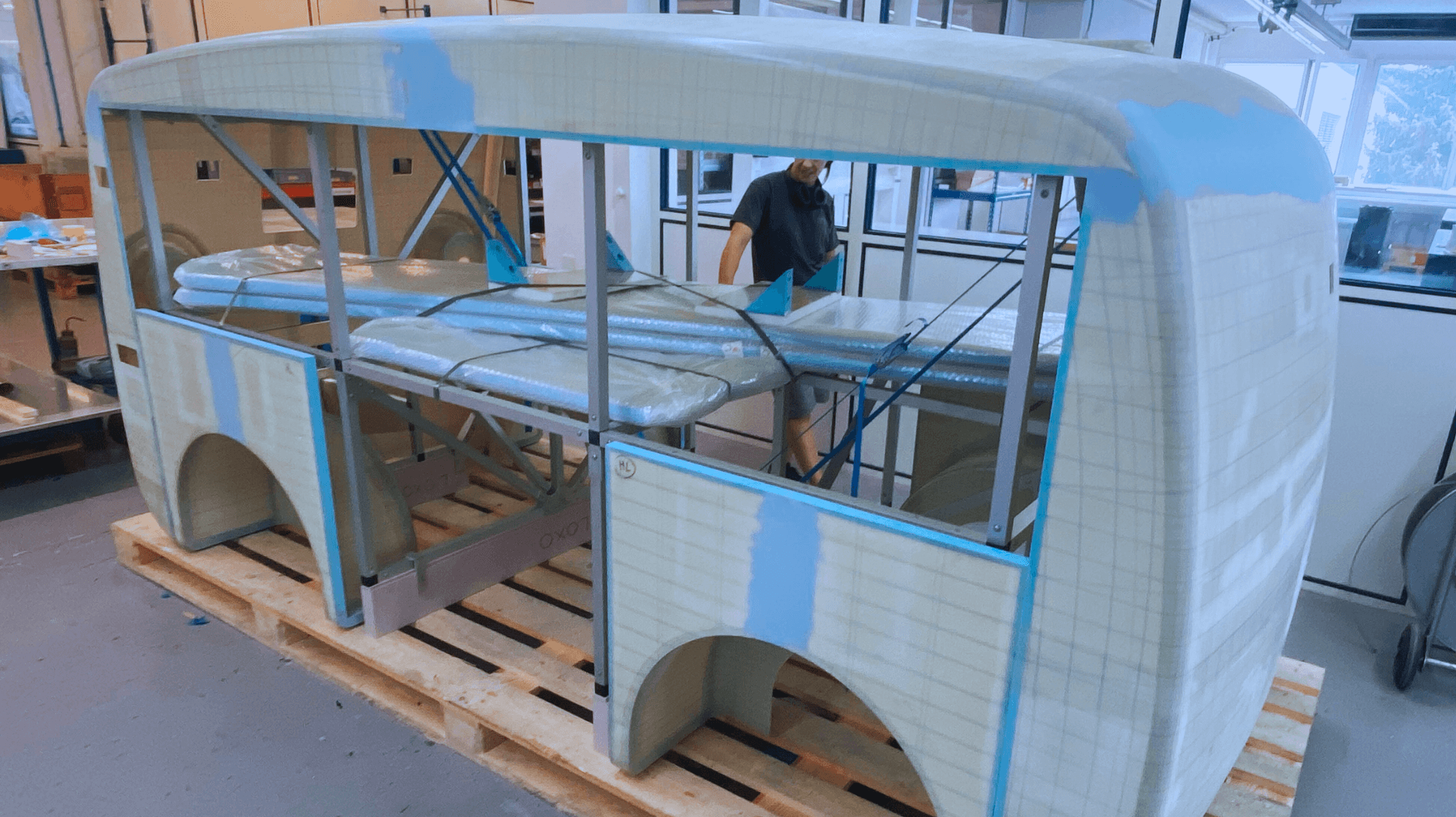

We provide modern and well-equipped CNC machining centres and are able to process besides all common metallic materials such as aluminium, titanium or stainless steel in particular composite materials such as CFRP, GFRP or many other fibrous materials. We realize small, medium, or large series projects no matter if the components themselves are concerned or their complex-shaped moulds with highest-quality surfaces. Our largest machine is able to process components up to a size of 3 times 5 meters. The other smaller high-precision 5-axis-machines allow for flexible and simultaneous machining operations with very high RPM (revolutions per minute) at the spindle.

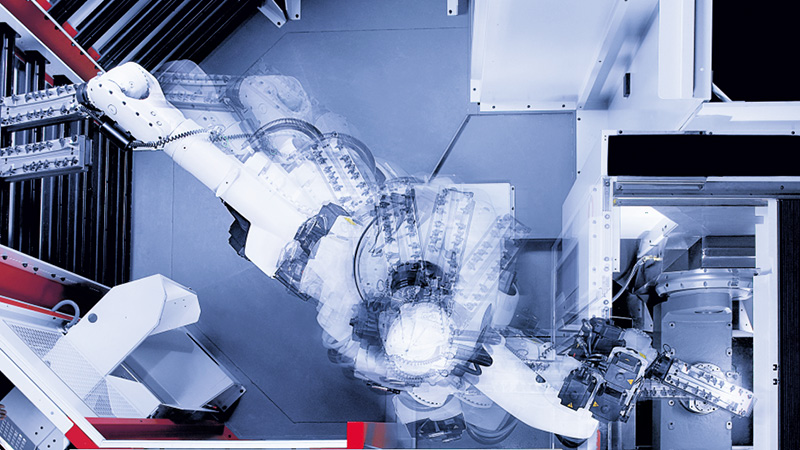

On top, we use a robotic arm for loading/unloading leading to following advantages:

- Fully automated process

- Fast loading/unloading

- High machine usage rate

- Short process cycles

- Highly efficient production system with storage shelves for 24/7 usage

As an example, some specification data of our CNC machine by Hermle:

- Max. dimensions X/Y/Z: 1000/1100/750 mm

- RPM 12 to 18 1000/min.

- Highly dynamic and simultaneous operations

- Precise 5-axis or 5-sides operations