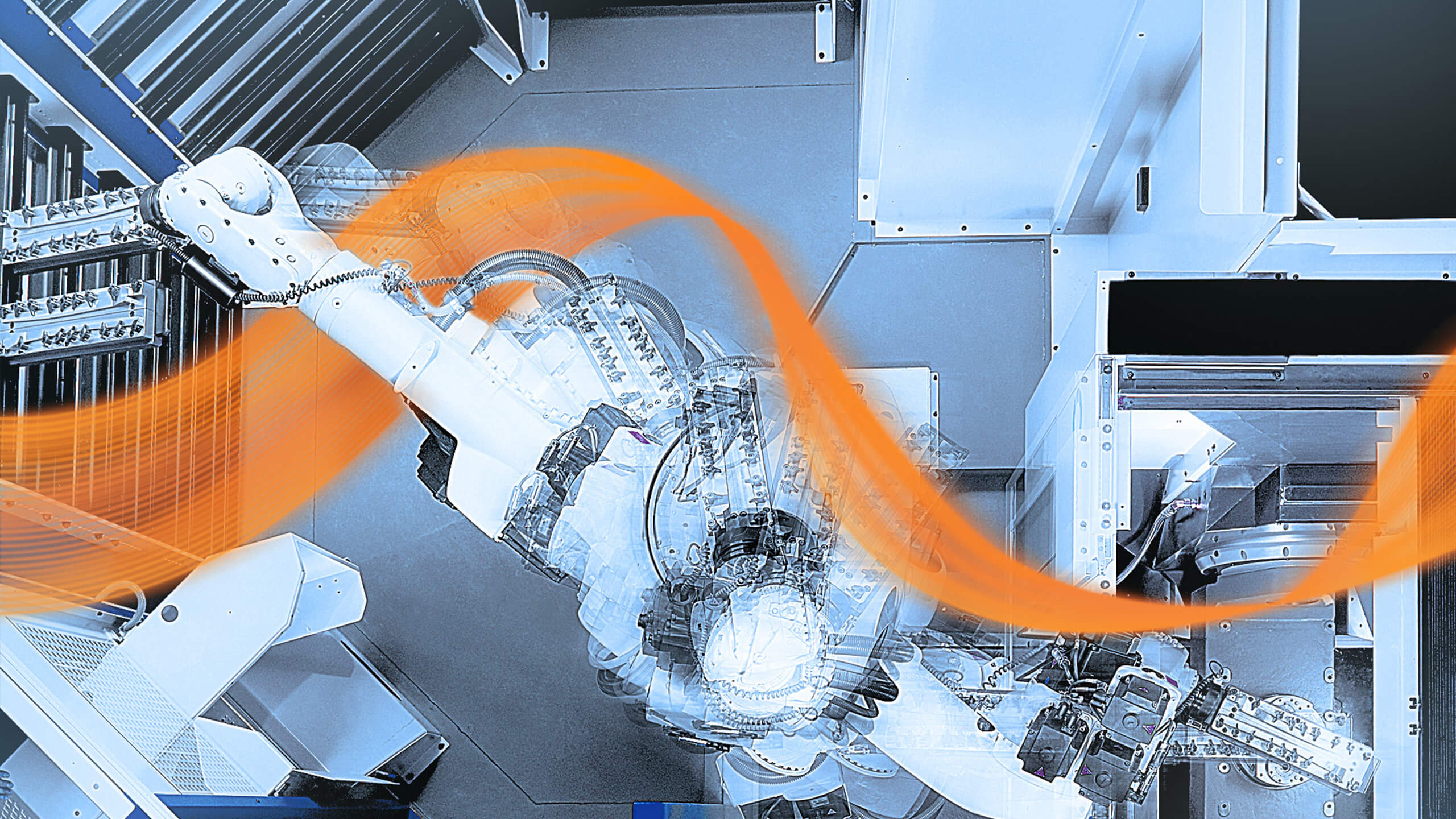

Engineering Precision. Delivering Performance.

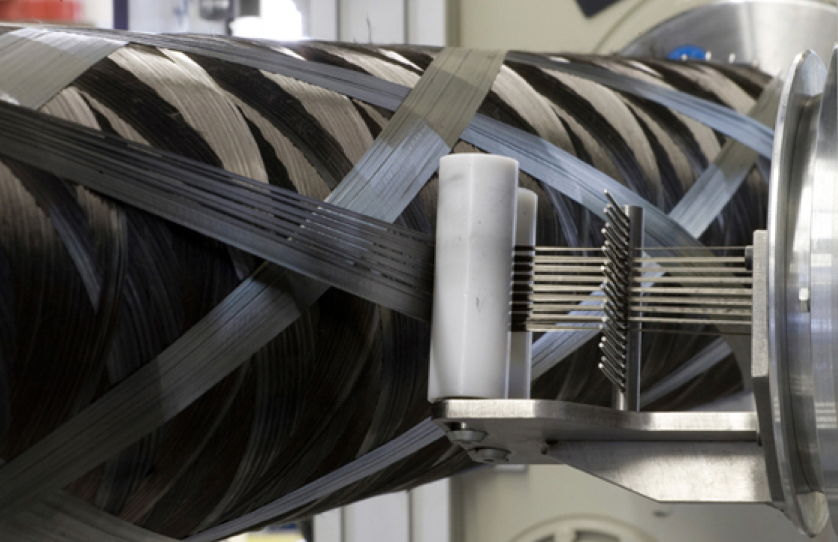

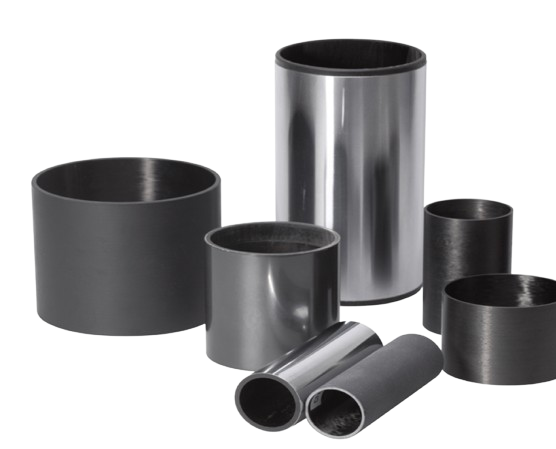

At Connova Group, composite manufacturing is the foundation of our engineering excellence. We specialize in transforming high-performance fiber materials into complex, precision-built components for mission-critical applications across aerospace, automotive, defense, and industrial markets. With over three decades of experience and a commitment to innovation, we combine material science, advanced production techniques, and quality assurance to deliver composites that meet the most stringent demands in strength, weight reduction, thermal resistance, and durability.